The building promotes the health benefits of consuming organic food. The owner brings together small (indigenous) agricultural producers to market products, generating income for low-income rural families and promoting production in urban orchards.

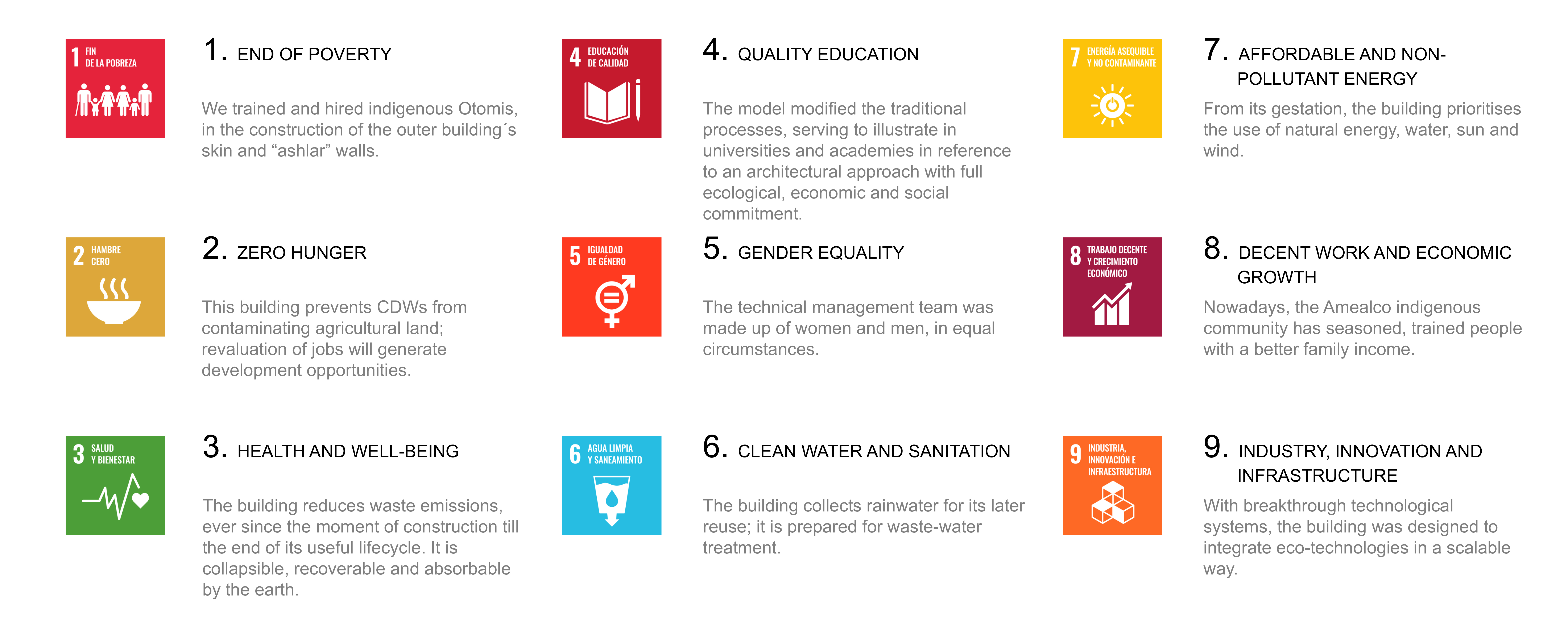

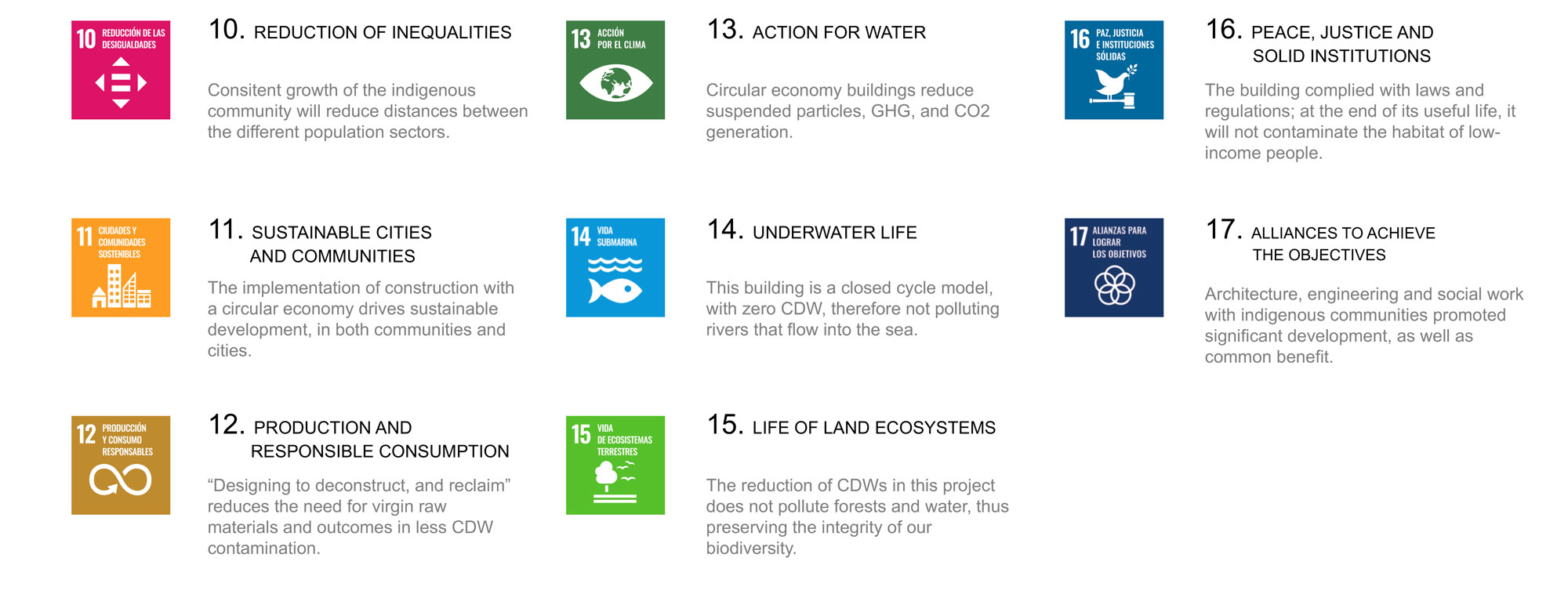

The design is based on biomimesis and circular economy, based on the choice of recoverable, reusable or recyclable materials; it includes the training and hiring of indigenous labor, and promotes the rescue of artisanal construction traditions.

The outer skin was made with regional and thermal ashlar, coming from the earth, same which will be later absorbed by it. It is planned to integrate ecotechnologies, but it does not depend 100% on them.

The architecture, with bioclimatic design, takes advantage of the sun, wind, water, and is planned with reduced investment and operation, (CAPEX, OPEX), demonstrating that any building can have a low carbon footprint and be environmentally friendly, within a low cost.

We are an organization fully committed to ecology, and the development of circular economy in reference to construction. Ever since 2009, we have successfully developed zero waste projects, consistently promoting the development of sustainable architecture through public and private spaces, same where we share our philosophy and valuable experience about the industry.

Our services are aligned to the best global practices in sustainable construction, with which we seek to create a balance between quality, functionality and ecological impact.

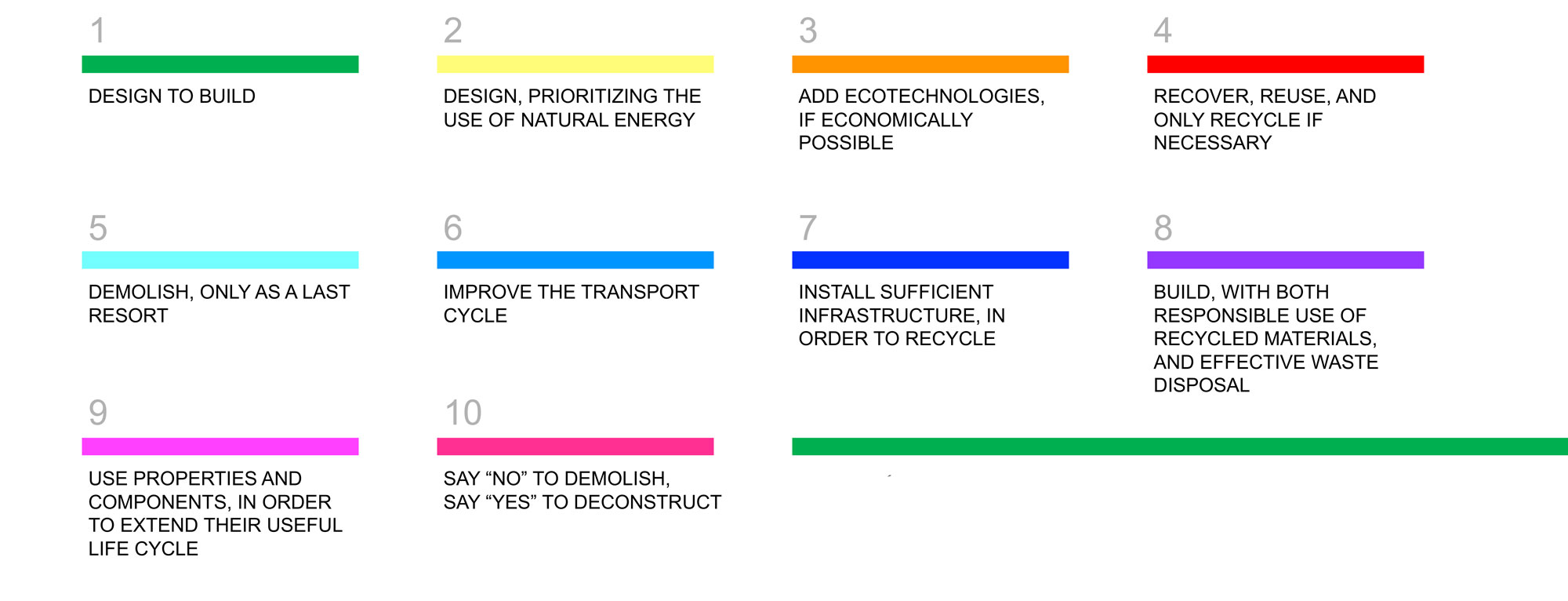

Our projects adapt to economic conditions and are continuously searching for solutions that reduce waste generation, whilst seeking optimization of our clients' OPEX and CAPEX, and promoting a truly sustainable architectural approach with an emphasis on redesign, recovery, remanufacturing and recycling for ecological and social economic benefit.

Aires de Campo, a company dedicated to the commercialization of organic food, was in search of a new architectural concept to develop its points of sale and distribution centers in the country. Currently, it works together with a network of more than 82 organic suppliers, among which are family farms, peasant cooperatives and medium-sized agricultural companies located in the Mexican Republic. All of them work within a framework of equality in order to achieve significant economic growth, social justice and environmental sustainability, as well as to develop the market for organic products in our country, making it increasingly available for more and more Mexican families.

Construction and Demolition Waste "CDW".

In Mexico, NOM-161-SEMARNAT-2011 considers as an obligation for builders that generate more than 80 m3 of waste in each one of their works, to formulate and develop the respective management plan. Art. 334 art. CDMX Penal Code sanctions with one to five years of jail to those who deposit a square meter of CDW

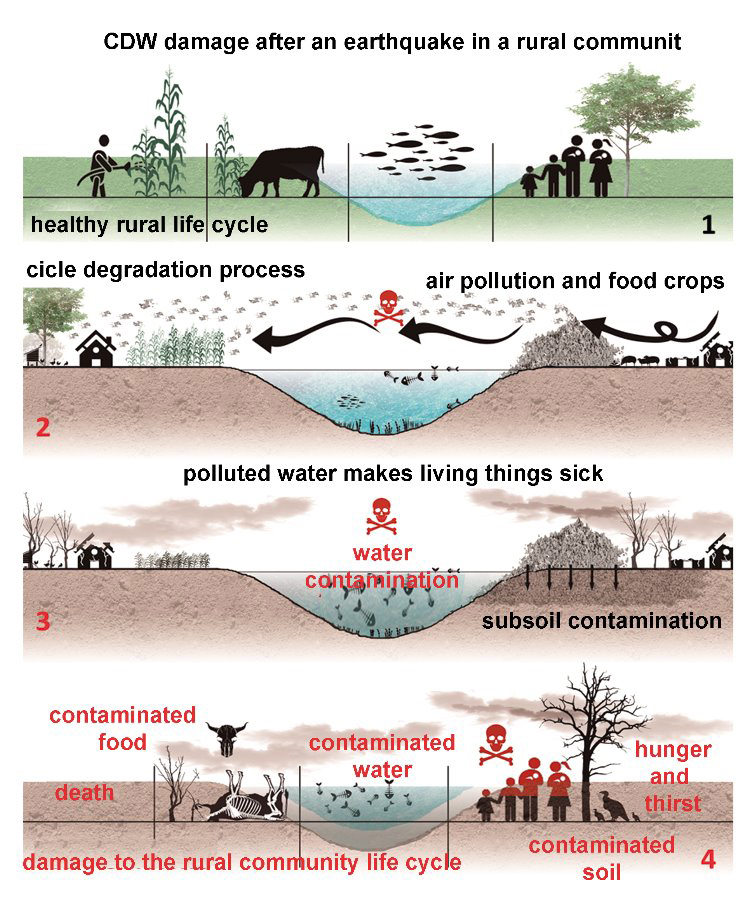

In CDMX, 13 thousand tons of urban solid waste and 14 thousand tons of "CDW" are generated per day; however, there are few sites close to the construction zones, fact which makes handling of this waste unfeasible. The cost for waste disposal in an authorized place is $ 32.00 Dlls, while the one for depositing it in clandestine sites is $ 2.00 Dlls. It is estimated that in Mexico City there are 400 clandestine dumps and just one recycling plant; yet, only 4% of CDWs are reused. The lack of valuation of "CDW". causes serious contamination, given that they contain toxic and dangerous components such as asbestos and fiberglass. Furthermore, they are thrown mainly into the open air, as well as in green areas, parks and gardens, or in small plots where poverty forces the farmer to receive them, putting food security at risk, but above all in the poorest city places.

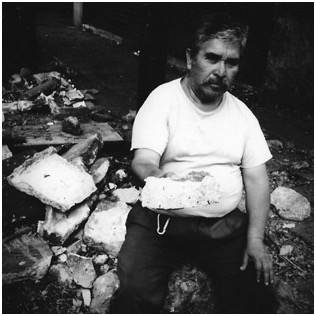

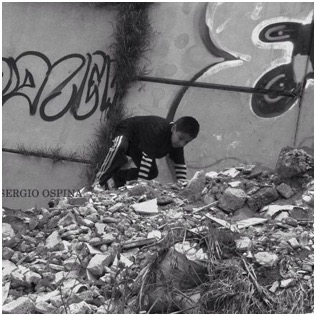

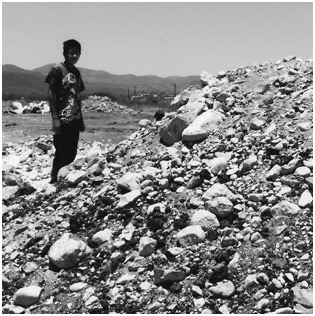

Both children are born, grow up and older adults die in the rubble, within this gray and polluted city environment. The dream of any person is to own and build a home, but this activity generates “CDWs” that due to ignorance are abandoned. Architecture, engineering and construction cannot be called sustainable in emerging countries such as Mexico City, where 5 million tons of construction waste continue to be generated, dramatically affecting the soil , same which in rainy seasons is washed away by rivers to the sea. The construction industry contributes 25% of the suspended particles and 30% of the "GHG" to the atmosphere of the CDMX. Indeed, we are talking about particles of less than 2.5 micrometers that lodge in the body, causing health problems such as Cancer.

During the earthquake of 2017 the lack of population´s knowledge in reference to CDW pollution, resulted in their use to slow the river´s growth during the rainy season, without realising that they have oxidants and pollutants which will harm underwater life, contaminating drinking and irrigation water for hundreds of years.

The city of Querétaro is located at a distance of 212.50 km from Mexico City.

Santiago de Querétaro, the state capital, has an extension of 759.9 km2, which corresponds to 6.5% of the total State extension. It occupies the seventh place in territorial extension in the State.

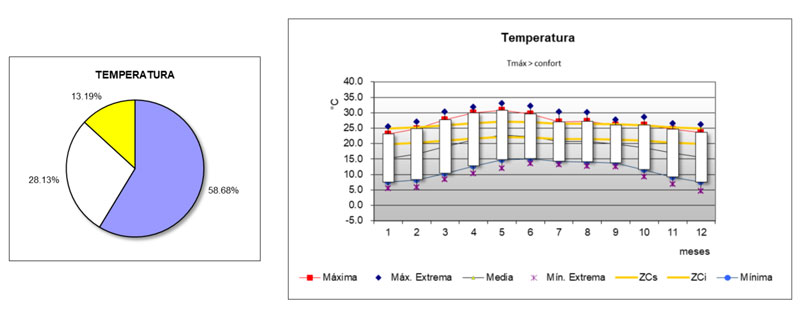

Climate is temperate, presenting very marked seasons of heat and cold.

At the beginning of the 20th century, the main economic activity was agriculture; in the second part of that century, industrial, commercial and service sectors began to develop with greater intensity. This city stands out for its economic growth, sustained by its industrial and real estate activity.

The building is located in Jurica, Santiago de Querétaro. The project is located within a low intensity commercial development; despite being a heavily wooded area, within the property there is a reduced number of trees.

The context is made up of a fast track, -“ 5 de Febrero Av.”-, a secondary road - “Paseo Jurica ”- and a residential área -“ Jurica ” -, which is characterized by horizontal residential constructions of Mexican colonial, and contemporary colonial style houses.

The concept is based on the forms found in nature: in other words, if we cut a lemon we find these lobar shapes. The same happens in a cucumber; when observing these fruits, they refer directly to the subconscious, relating them to the idea of health, and beneficial foods.

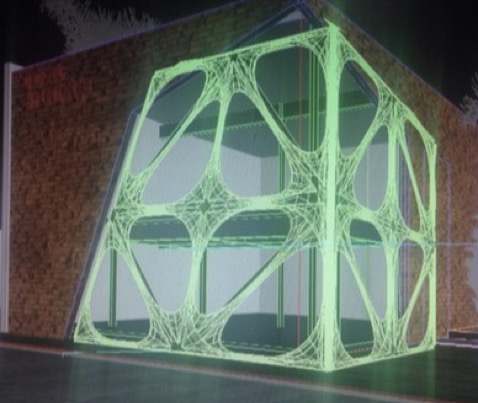

Parametric design is an advanced digital design technique that allows the introduction of a series of variables or parameters, such as spatial limits, volumes or temperatures, in specialized software, in order to manipulate them through algorithms and thus obtain more complex, versatile and original geometric designs. With this new way of doing architecture, the building's facade was developed.

The ABM design team worked on various concepts, yet inspiration came based on existent nature´s geometry: a conceptual design was devised that conveyed the brand values, consisting in the offer of authentic products, just as handmade, both natural and fresh from our land. The idea was to create a building governed by the principle of biomimicry, the science that studies nature as a source of inspiration, in this case, bioarchitecture, which has as its basic principle the harmonious integration with the environment, using in its favor both environmental conditions and natural resources. In addition to these principles, the project was conceived thinking about the importance of building a resilient building, for which we had to plan it based on the principles of deconstruction and circular economy.

Although we believe in the principle that form follows function (and function follows form), this building should render iconic for the brand, with a clean but high-impact shape, characteristic and unique, yet at the same emotional. This authentic form was coined from the union of two cubes, with additional interaction from a natural green element.

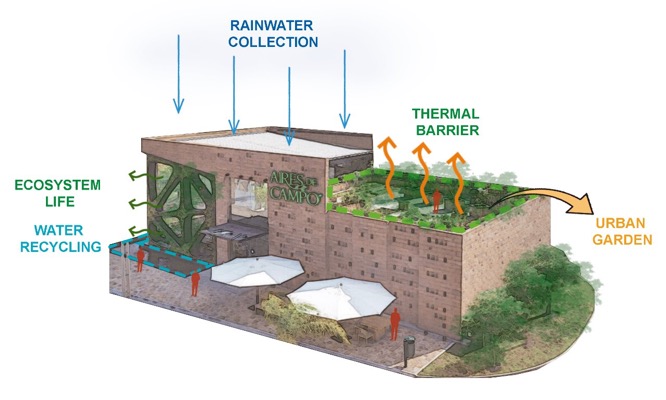

PASSIVE SYSTEMS

Analysis of the natural environment. Use of natural, handmade materials.

ACTIVE SYSTEMS

Clean energies. Use of low energy consumption technologies.

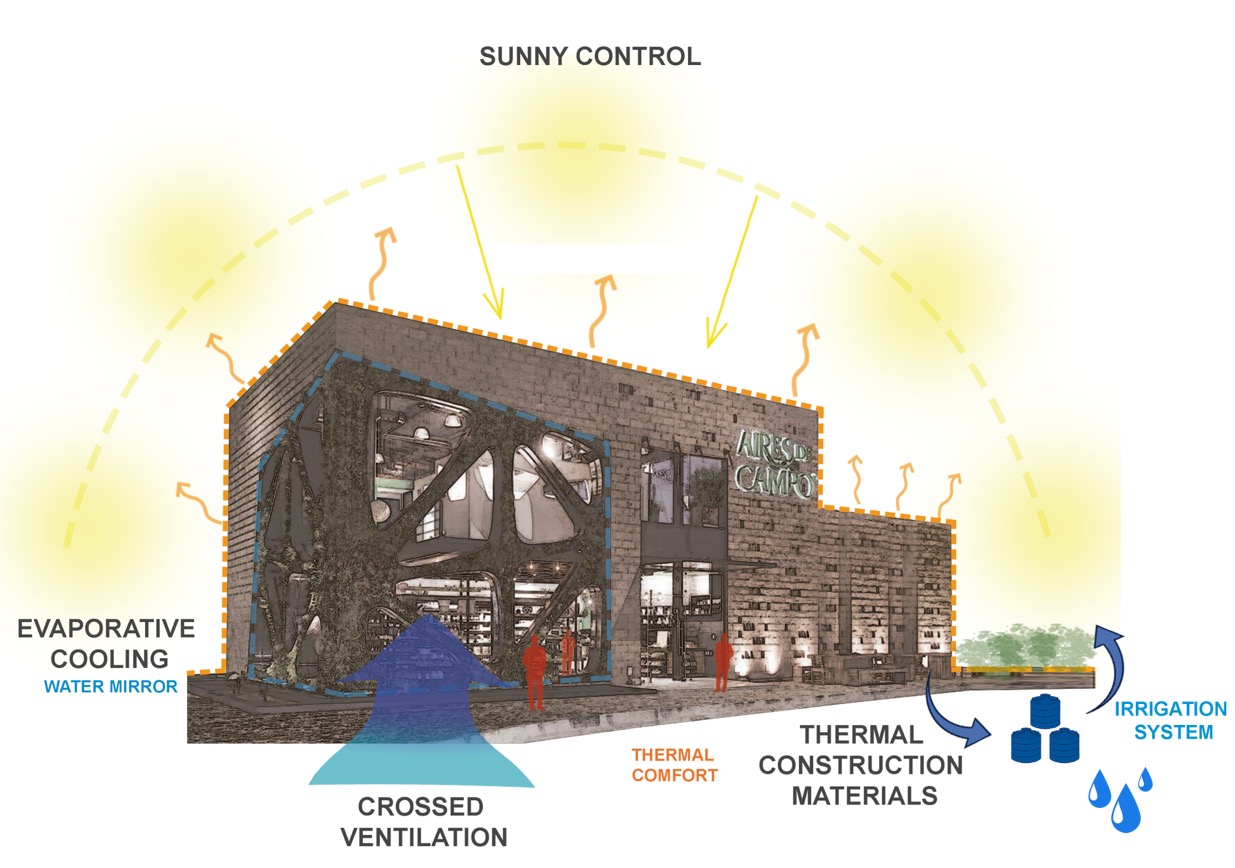

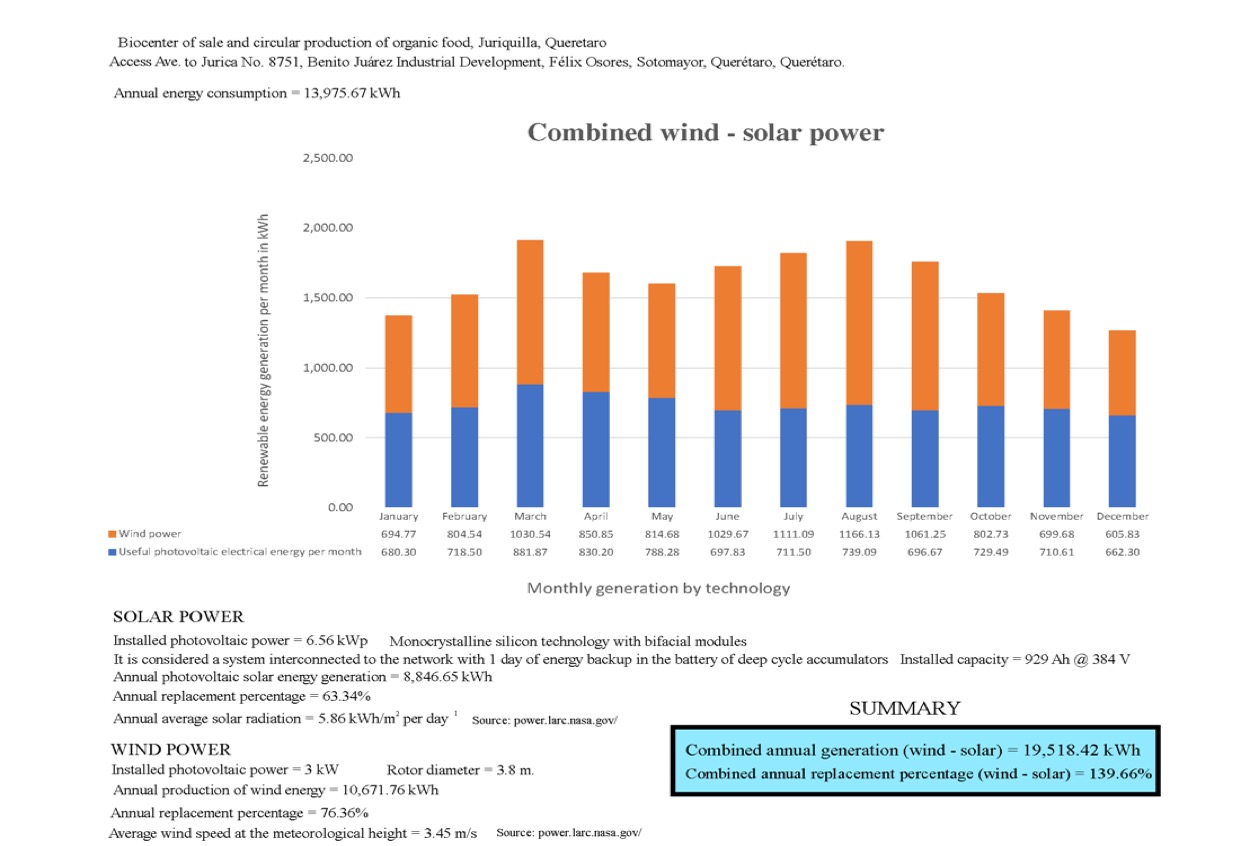

The project is designed to operate with the lowest energy consumption, giving priority to the use of air, sun and water. It is scalable, given that technologies can be integrated according to client´s budgetary possibilities.

WHILST NOT BEING 100% DEPENDENT ON THEM IN ORDER TO DEVELOP A COMFORTABLE BUILDING.

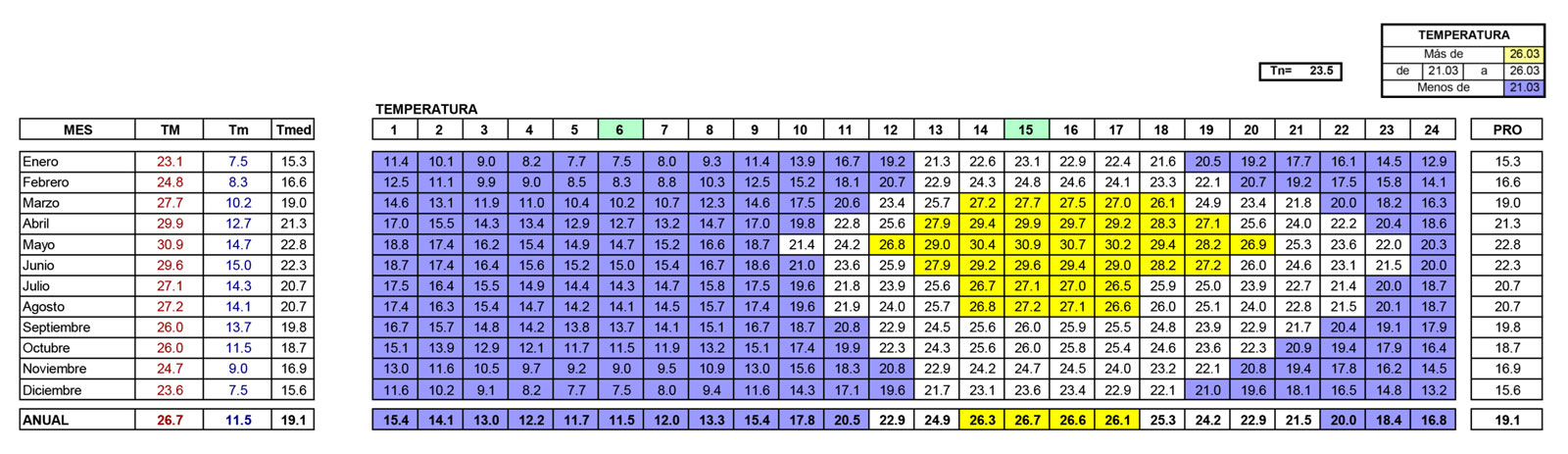

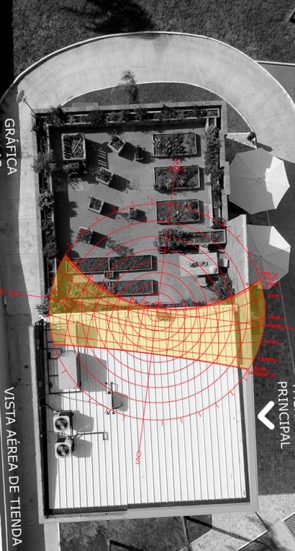

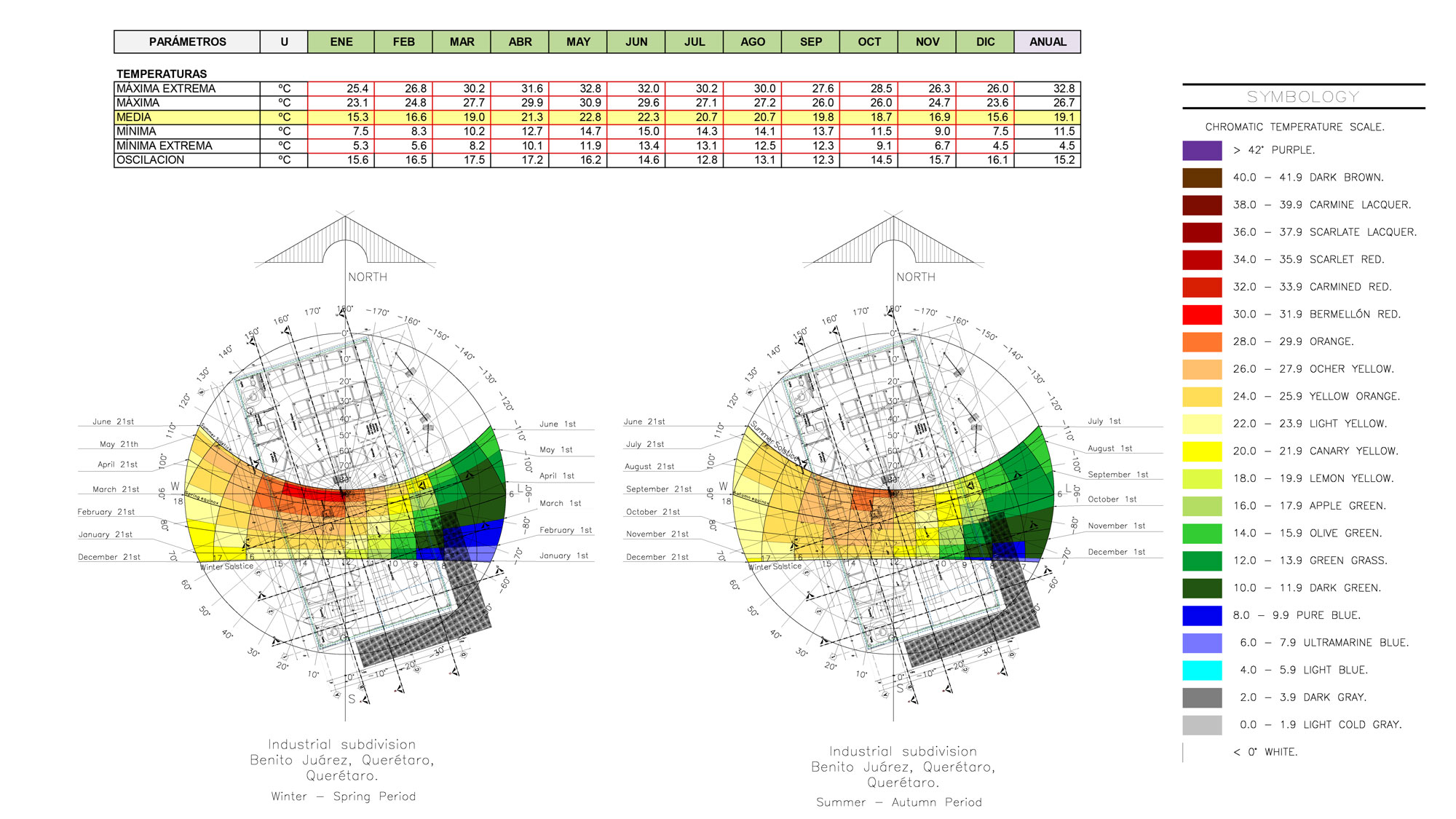

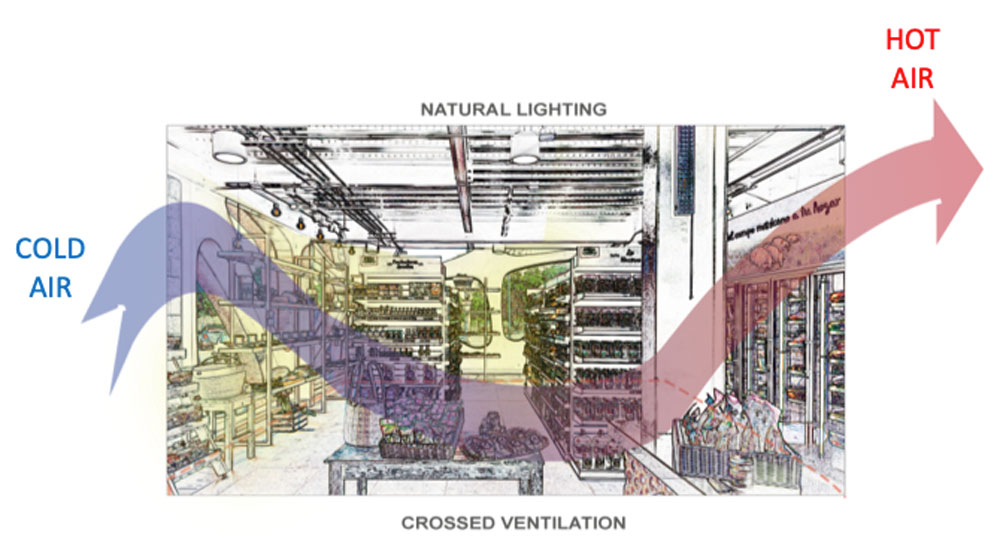

It is observed that the annual temperature is on average below thermal comfort, which is why solar radiation is used as a heat source during the mornings, while in the afternoons direct radiation is blocked by means of a green lattice, which Avoid using air conditioning.

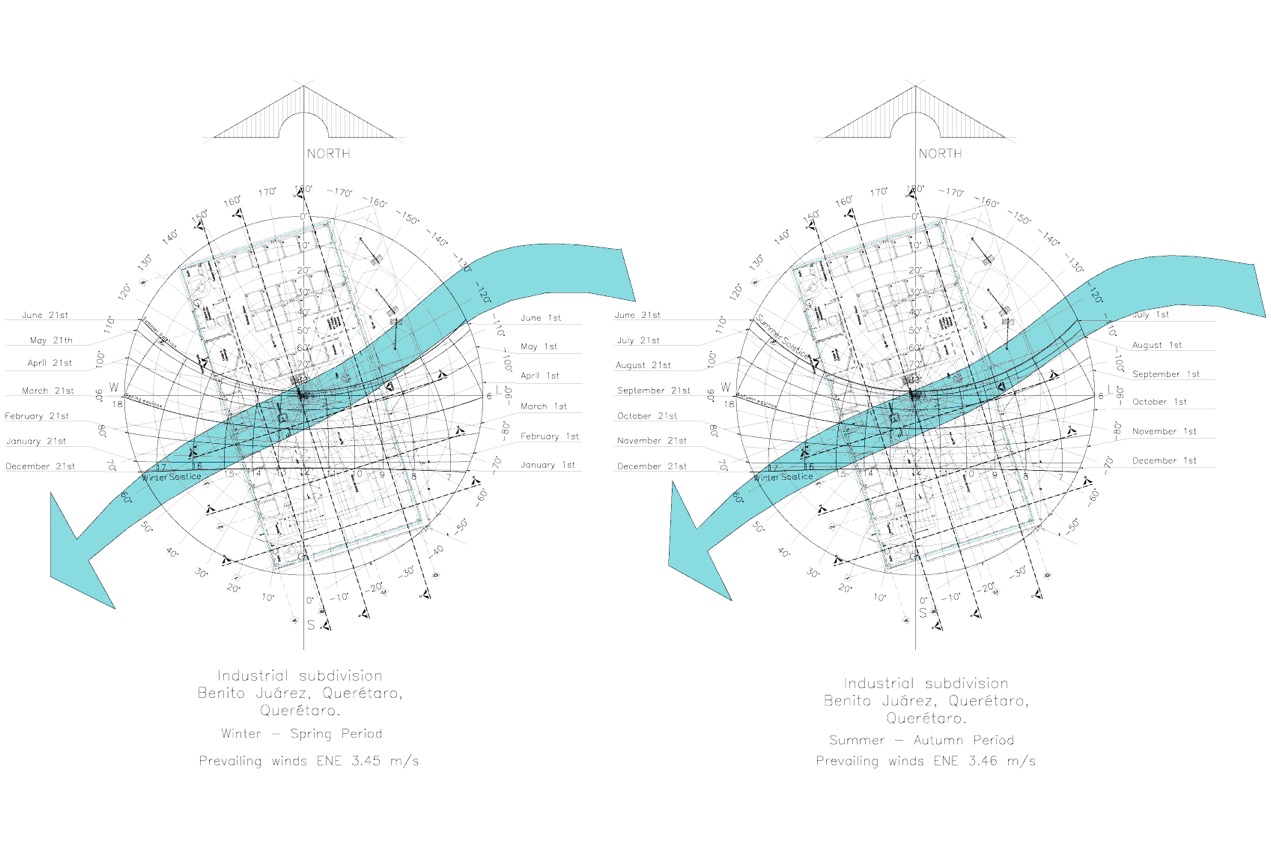

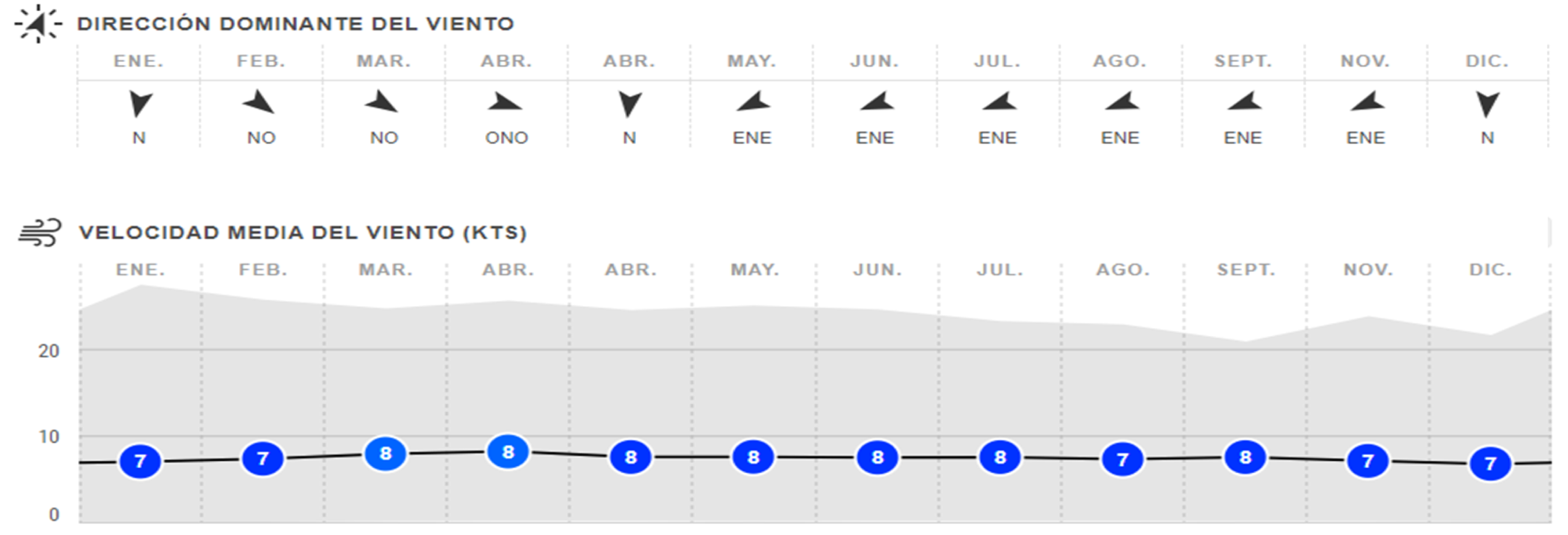

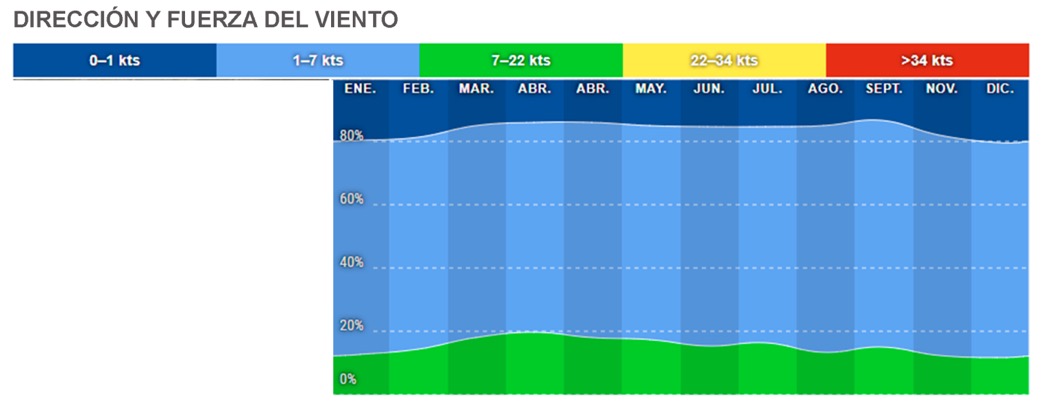

The prevailing wind comes from the northeast, so the flow is used for cross ventilation. The average speed is between 7 and 8 km / h.

The use of the wind flow favors cross ventilation, therefore the temperatures reached are optimal for the performance of the activities of the building.

The materials used for the construction of the building envelope, ashlar, have very high thermal properties, so the building is capable of reflecting sunlight and thus avoiding conduction heat gains. During the night, the absorbed heat will dissipate inside, heating the space in cooler hours.

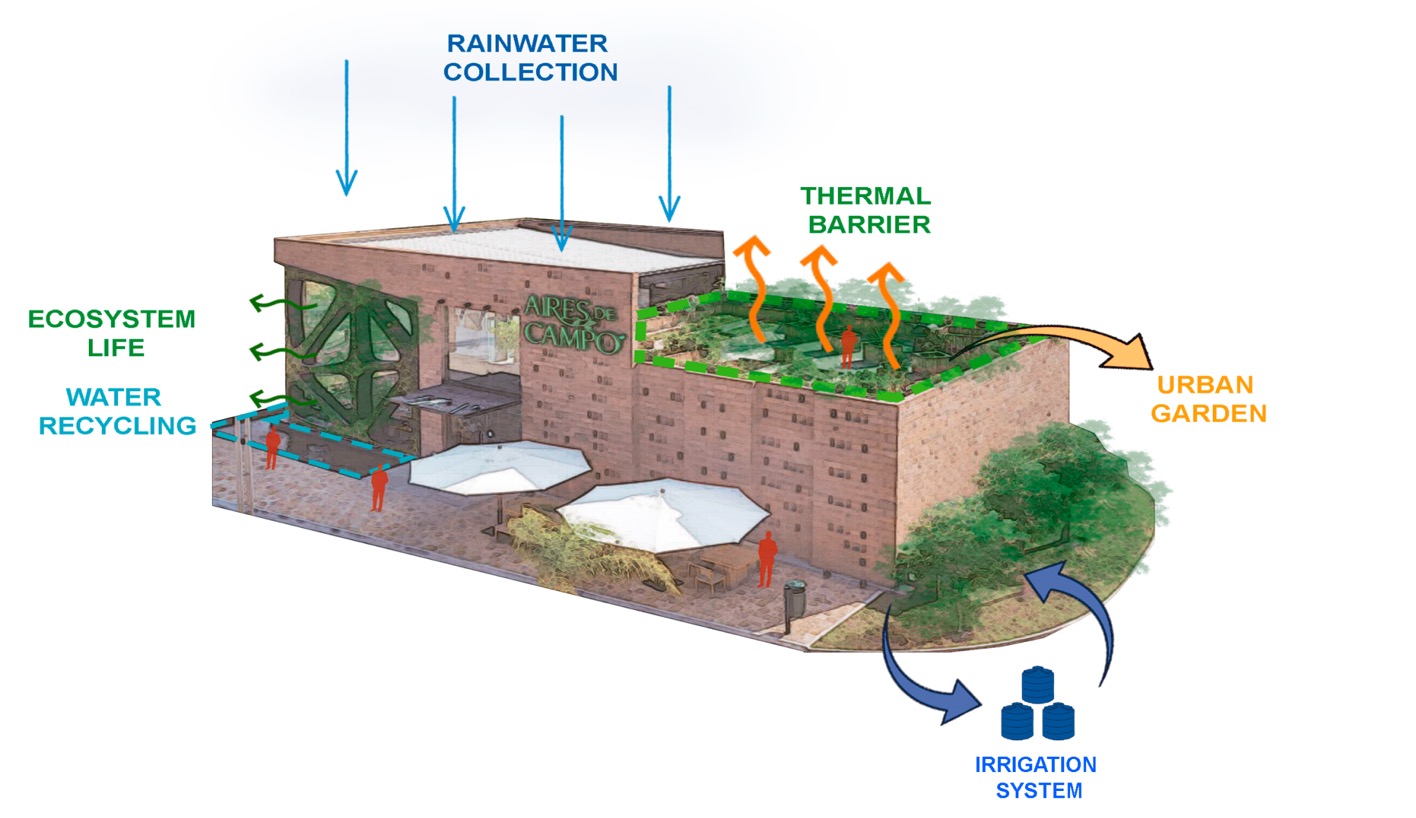

Rainwater is used and reused in the water mirror, which works as an evaporative ventilation element. The urban garden located on the roof, serves as a plant barrier to the interior due to solar radiation and as a point of food generation. The areas destined for ecosystems are increased.

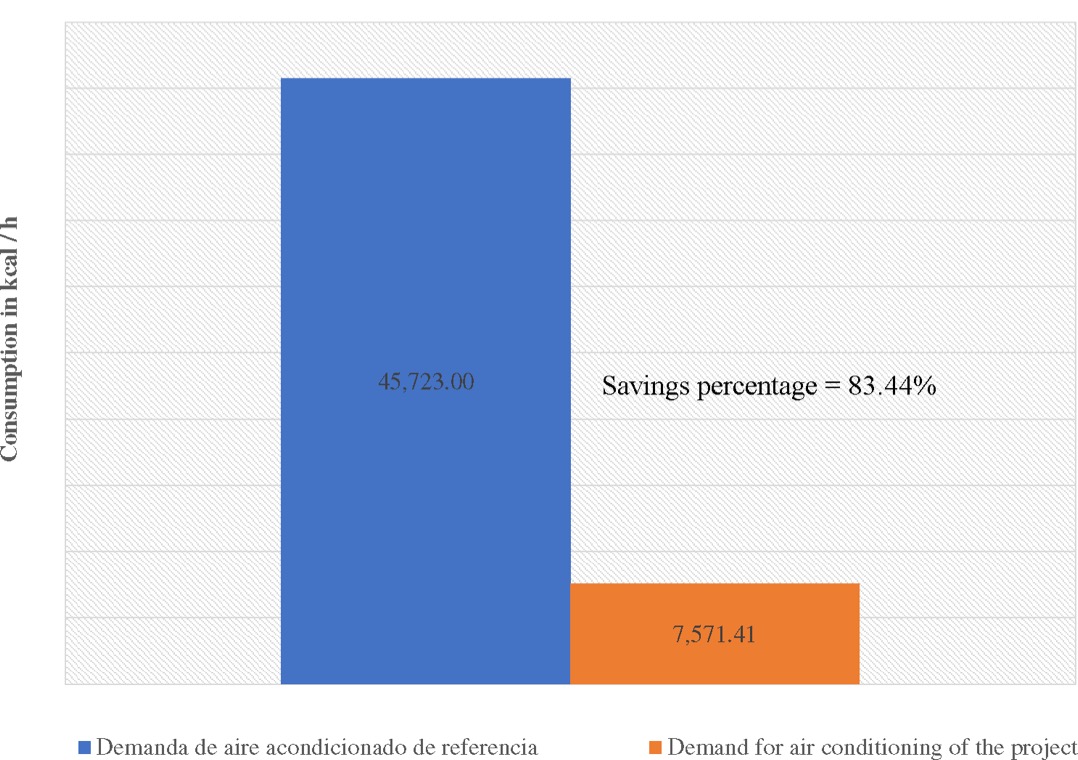

Cross ventilation favors thermal control during the hot hours of the day, so the use of an air conditioning system is not necessary, thus achieving great savings in the consumption of electrical energy and CO2 emissions into the environment. The building reduces the dependence on technical equipment for energy saving but can be added according to the economic capacity of the client

A building that uses a commercial air conditioning system and in the same atmospheric conditions, would consume around:

while the Biocenter consumes only:

having reduced the number of equipment installed to keep the space within the comfort range. The passive design strategies used are:

THE BUILDING

PROGRAM

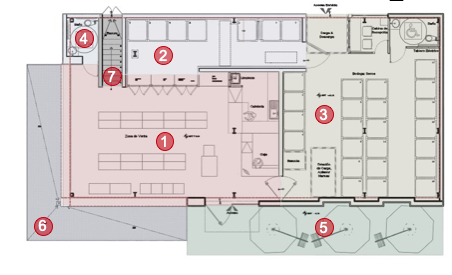

1. SALES. 88.44 M2

2. COLD WAREHOUSE. 33.41 M2

3. DRY WAREHOUSE.. 91.36 M2

4. SERVICES. 5.53 M2

5. TERRACE. 39.64 M2

6. WATER MIRROR. 32.04 M2

7. CIRCULATIONS. 5.22 M2

TOTAL M2 295.64 M2

PROGRAM

4. SERVICES. 11.74 M2

9. CIRCULATIONS. 28.43 M2

10.OFFICE. 40.69 M2 7

11. ORGANIC ORCHARD. 33.41 M2

TOTAL DE M2 202.53 M2

This 95 to 97% recoverable building has served as a success story to share experiences in universities and academies, raising public awareness on the fact that, even with limited investment levels, a project with social, economic, environmental commitment and a low ecological footprint can be accomplished. This Circular Economy methodology can be adapted and replicated at any scale and in any building or house, given that it takes up the basic principles of biosustainable architecture.

In order to have a positive social impact, we strove to look for the material with the least carbon footprint, that is, whose manufacturing procedure was as natural as possible, and manufactured in a nearby area. And so it was that, searching in the surrounding towns, we found a small town inhabited by Otomí indigenous people, many of them in conditions of poverty due to the lack of job opportunities, and whose income is based on the extraction of natural ashlar from tepetate.

This activity had fallen into disuse, due to its being replaced by mass-produced materials, which require more fossil fuels and energy for their production, such as cement blocks.

By using this material, we rescued artisan traditions and Mexican popular culture; what is more, nowadays more indigenous families will have income from decent trades. This knowledge will have a multiplying effect, same which in turn shall result in the recomposition of the social fabric. By promoting these resilient practices in a greater number of projects, we will contribute positively to the community, the population and the country.

To achieve a Zero Emissions Building, the design begins by basing the project on the four principles of Circular Economy, fully aligned with the 17 SDGs, and thus a scalable Project, adapted to the clients´s budgetary possibilities is accomplished.

In nature, the concept of garbage does not exist; the project was planned so that 97% of materials are recoverable, reusable, recyclable or reabsorbable, used in a subsequent construction and does not become CDW. We strove to recover materials such as steel, glass, wood, electrical components, hydrosanitary ware, whilst recycling concrete, ceramics, and reabsorbing the building´s outer skin. It Included rainwater harvesting for its later reuse in toilets, urban garden irrigation and green façade.

Living systems run on renewable sources. The building was modeled to optimize the natural use of wind, sun and water, and allows for the installation of cutting-edge technologies such as photovoltaic panels, wind turbines or biodigesters.

In the design, analyses were used through several computer programs that simulate the historical climatic conditions of the site, with this information, natural bioclimatic passive systems were integrated in order to save energy, and reduce the use of equipment that works with non-renewable energy.

By minimizing the use of artificial lighting during the day or indoor air conditioning systems, electricity consumption and fossil fuel consumption were reduced. Ecotechnologies can be integrated, but it does not depend 100% on them to be a comfortable building.

The concept of the building is to function with the most basic equipment, guaranteeing aesthetic beauty, functionality, whilst foreseeing a truly sustainable low-cost future, a model that, when replicated, could lead to a future Zero Emission.

From the conceptual design of the project, it was thought as a “zero emissions” building, same which at the end of its useful life, would have its materials recovered practically in their entirety. The basic structure is made of removable steel profiles, steel mezzanine slab with concrete, with an upper cover of insulating thermal panel; most importantly, the facade or building´s outer skin would be built with a material produced in the Amealco region, less than 50 km from the project site, and displaying thermal insulation capacity. For the interior - and in support of deconstruction - the project had 95% of its pipes in a visible manner, with practically all objects inside being removable and recoverable The need for air conditioning was greatly reduced thanks to the bioclimatic design properties, and the materials used.

Ashlar has a lower carbon footprint, solidifies with the sun, and can be recovered or reabsorbed by the earth; indeed, it is manual work that has been done for generations, and whose traditions are not conflicted with contemporary architecture. At the end of the building´s useful lifecycle, and when demolished, the material is fully absorbed by the earth itself. Due to the shortage of CDW dumps in the area, the use of construction systems that generate the minimum of CDW - such as ashlar - were prioritized.

En varias ocasiones el equipo de construcción me comentó que podríamos construir el edificio con materiales prefabricados más rápidos de instalar, decidí optar por la utilización de este material por su baja huella ecológica, pero sobre todo porque podríamos brindar preparación técnica a indígenas a fin de que tuvieran un oficio bien remunerado y con ésto generáramos empleos e impactáramos positi- vamente a esta comunidad

Data from Global Footprint Network, indicates that Mexicans need 3 hectares per inhabitant so as to satisfy their consumption and absorb their waste, almost triple than the Mexican territory offers.

In order to contribute and improve this situation, the following measures were adopted in the development of this building:

Illustrate the basic concepts of traditional architecture. Promote indigenous participation in vulnerable conditions, Seek social integration through education and training, creating a league with the most developed communities in order to achieve community benefits, This contemporary architectural piece reflects the indigenous artisan value, therefore encouraging the visitor to reuse these constructive traditions in future projects. The project selected a low-income Otomi indigenous community: Amealco, Querétaro, located less than 50 km from the project site, is dedicated to the artisanal manufacture of ashlar (sun-dried earth blocks), with thermoacoustic, aesthetic properties and a very low carbon footprint.

This community was economically relegated, putting the existence of this beautiful trade at risk, due to the use of other construction materials, such as cement block, which consumes many virgin raw materials and fossil fuels in its manufacture, without the consumer knowing the significant pollution that this production generates. The success of the project was verified: during the construction it was planned to train 46 ashlar setters and due to the revaluation of this work, more than double had to be trained when they were required by other local builders, given that they render a qualified and coveted workforce due to its scarcity in the region. The production, consumption and placement of the ashlar directly combats poverty. The benefits to the Amealco indigenous community create resilience, and today 86 families enjoy a better paid income. In case of continuing the bad practices of demolition and deposit of waste in green areas, the ashlar and the building will not contaminate the land, the water, the air, the biodiversity and the health of the community.

We opened two large windows, with a metal structure based on the fractal geometry of nature, and inspired by the principle that when a fruit is cut, its interior reveals a geometric shape within curved segments. Said metal structure - in its central part - was designed to house natural vegetation that serves to generate oxygen and, above all, to function as a natural habitat for various insect species, same which contribute to increasing pollination and preventing the entry of direct sunlight. At the bottom of this “live” metal structure, a pond that works as water mirror was located, reflecting this green structure, and capturing irrigation water surplus from the green wall, as well as rainwater. This can be later used for irrigation, refreshing and humidifying the environment in an adjacent area to the access; in this way, a biological circle is created in the building.

“THE MOST SUBLIME PRINCIPLE OF BIO-ARCHITECTURE IS TO TAKE NATURE AS AN INSPIRATION SOURCE”

…at the end of the building´s useful lifecycle, and when demolished, this material is easily absorbed by the earth, given that it is part of it, one hundred percent.

Architect from the National Autonomous University of Mexico. He has 33 years of professional experience, 14 dedicated to the successful implementation and construction under the Circular Economy Community scheme. He leads multidisciplinary teams of Architecture, Engineering and Construction. He has developed housing, residential, restaurant, hotel and building projects for various global clients and companies such as FCB, LOWE LINTAS & PARTNERS, CARAT, OLABUENAGA & CHEMISTRY, McCANN ERICKSON, RICOH, Aires de Campo. In 2008, concerned about the serious problem generated by construction and demolition waste (CDW), he founded ABM Arquitectura Biosustentable Mexico for research, experimentation and development of sustainable and recycling projects.

In 2008 BMW Germany accredited him as a certified architect for Latin America for the design and development of BMW, MINI and MOTORRAD agencies. In 2009, he began experimenting with architectural projects based on 4R principles. He was a lecturer on Sustainability and Recycling, at the International Festival of Creative Recycling in 2010. In 2011, he obtained the most important award from the Mexican government and the private initiative (COPARMEX-SEMARNAT-CONAGUA) with the National Prize / Environmental Cooperation and Recycling, for the project "The value of recycling in the remodeling of buildings". He participated in Mexico´s Design Week, presenting an installation made in 97% with materials from the 4R system, for the transmission of values on the handling of waste from PET bottles, same which pollute river and sea waters throughout the country.

In 2012 he was invited to attend the World Congress on Renewable Energies in Denver USA, as well as the Study of Sustainable Urbanism for the ZMVM in the Continuing Education Unit of the UNAM. Moreover, he participated in the creation of the Mexican Standard for Sustainable Building. In 2013, he gave the conference "The importance of recycling in construction" at UNAM. Soon afterwards, he registered the book “Master Plan for Environmental Improvement through the Urban Project for Collection, Recycling and Re-insertion of Construction and Demolition Waste from the Mexican Republic”. In 2014, he was invited to learn about the recycling processes of CDW (Construction and Demolition Waste) by the Association of Recyclers from Germany, Denmark and Sweden; furthermore, he then visited companies specialized in handling CDW (Construction and demolition waste) in Spain and the USA. In 2015, he led a specialist group and created a comprehensive model for CDW management. In 2016, his team was chosen by OBRAS magazine as one of the 10 Change-Generation Offices in the country for his career in developing resilient projects.

He has developed projects for global companies in which the UN sustainable development goals are met, and in which people from indigenous communities, such as the Otomí de Amealco, have been trained, and taught paid trades in the construction industry. In 2020, he was appointed representative of the College of Architects of Mexico City and the Society of Mexican Architects CAM-SAM for the modification of Standard 007, for the management and recovery of construction and demolition waste. The same year he carried out studies of circular economy with the Delft University of Technnology endorsed by the Ellen MacArthur Foundation. He is a lecturer in methodologies on Circular Economy; he is currently working on the implementation of urban planning methodology, Big Data, gender inclusion, sustainable / resilient growth and zero waste, under the principles of Circular Economy. He is the author of the book ”THE CIRCULAR REVOLUTION” (Design, Recycling, Resilience and Construction in a Circular Economy). Today he teaches conferences at undergraduate, master and PhD university levels.